Wind tunnels are infrastructures used to test the interaction of objects with air flow. Aerodynamic investigations in designs need to be carried out in three stages, namely numerical modeling, experimental study (wind tunnel trials) and flight trials.

Wind tunnel tests are very important because of the reasons that the analysis of air flow using numerical modeling takes a long time and needs to be verified, and real experiments can be complicated, expensive and dangerous. In wind tunnels used to evaluate the suitability of designs safely, quickly and cheaply, aerodynamic examinations of all objects interacting with air can be made.

Wind tunnel trials are one of the important processes that must be applied to verify numerical analysis and to make flight trials cost effective and safe.

Many experiments can be carried out in wind tunnels, such as examining the aerodynamic properties of aircraft, helicopters, UAVs, parachutes and land vehicles such as cars, trucks, buses and motorcycles, determining the interactions of objects such as sirens and lightning rods with air and analyzing their resistance in the storm environment. The construction of the Ankara Wind Tunnel, which is a symbol of the reputable civilization level of the Republic, its activities to produce its own technology and its own production, was started in 1946 and its construction was completed in 1950.

Ankara Wind Tunnel (ART), which has been regularly maintained, repaired and upgraded by TÜBİTAK-SAGE since 1993, is a wind tunnel with closed circuit, horizontal cycle, atmospheric and closed test chamber operating at low sound speeds. The test room is 3.05 m wide, 2.44 m high and 6.10 m long. The tunnel cycle is reinforced and the test chamber is made of wood.

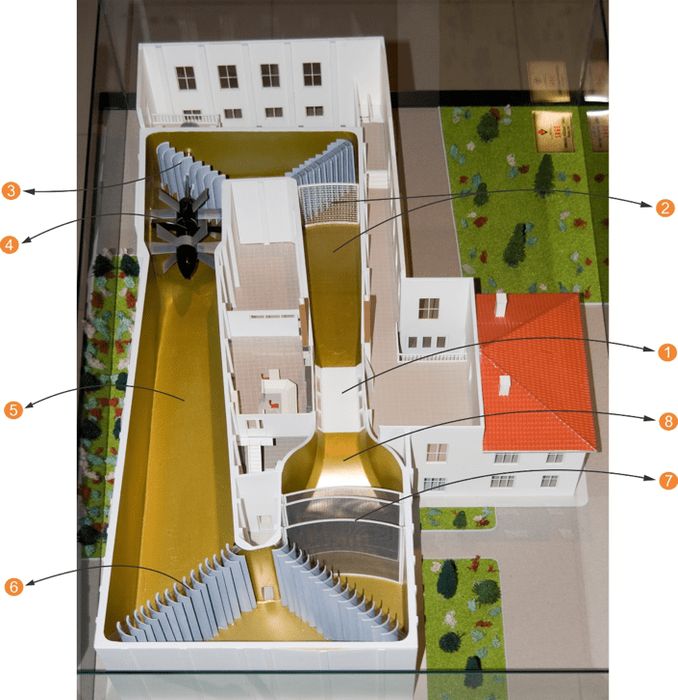

If the model is not available in the test room, a speed of 80 m / s (288 km / h) can be reached. The axial turbulence level of the tunnel is 0.15% and the total turbulence level is 0.62%. In the figure below, the sections and technical features of the Ankara Wind Tunnel are given on the scale of 1:50.

Tübitak SAGE Institute Director Gürcan Okumuş shared his Twitter account on the subject.

"If it could be completed in the 1950s as planned, it would be one of the few wind tunnels in Europe."

Services Provided by Ankara Wind Tunnel

Four different types of tests can be carried out in the Ankara Wind Tunnel: load measurement tests, structural strength tests, flow measurement tests and flow display tests. The design and production activities of the model to be tested according to the wishes of the customers can be carried out by us. Flow measurement tests using external balance, internal balance and model mobility system (Eng. Model Support System), flow measurement tests using Constant Hot Wire Anemometer (Eng. Constant Temperature Anemometer (CTA)) and miniature multiple pressure meter (Eng. Scanivalve) imaging tests are carried out using pressure sensitive paint system (Eng. Pressure Sensitive Paint), strand, oil and smoke.

Face Measurement Tests

Load measurement tests are carried out when it is aimed to determine aerodynamic loads. In order to find the aerodynamic forces and moments that affect the model in different speed, angle and model configurations, external balances and internal balances are used, and model mobilization system is used to bring the test model to the desired angle. Wind tunnel balances consisting of various hardware and software components make it possible to measure with high accuracy and reliability.

Structural Strength Tests

In these tests, the model is integrated in the test room and the desired geometric conditions, speeds and times are given wind, and it is checked whether there is any deformation or rupture on the model. The test model can be integrated into the model mobilization system according to the customer's request, and the tests can be performed in different angle configurations or in a single configuration by integrating the test room floor.

Test Model Design and Production

Wind tunnel models are generally produced using aluminum, steel, composite or wood materials. Design and production activities are carried out by using materials with sufficient strength to carry the gravitational force and aerodynamic forces acting on the model, to change shape at least during the test and not to damage the model and the tunnel as a result of part breakage. Model production can be done by us or by the customer. In the options of the model to be produced by us or by the customer, the minimum document sets required for test safety should be agreed before the test. Related documents consist of three-dimensional model and technical drawings of the test model (whole / sub whole). These documents are examined by TÜBİTAK SAGE in terms of manufacturability, interfaces, reliability, strength and dynamic properties, and a technical opinion is given to the customer.

Ankara Wind Tunnel Sections and Features

| * | SECTION NAME | FEATURES |

|---|---|---|

| 1 | Test Room | Dimensions: 3.05m * 2.44m * 6.1m |

| 2 | Expansion Cone And Metal Sieve | Widening angle: 5 ° (horizontal), 6.3 ° (vertical), Length: 15m |

| 3 | First Two Row Swings | In the first two corners, the edge of attack is concrete, the trailing edge is wood. |

| 4 | Propeller And Rectifier Blades | 5.18 m diameter 4-blade propeller, with a DC motor with a power of 220 hp (1000 kW) on a 750mm diameter shaft, the highest 600 rpm; 7 rectifier blades. |

| 5 | Second Expansion Cone | Widening angle: 6.4 ° (Both directions), Length: 24.5m |

| 6 | Second Two Row Swings | 22 swivel fins with the same cross section, assault edge concrete, trailing edge wooden material. |

| 7 | Current Regulating Curtains | 1 pieces of one piece of metal at 3 m intervals before the contraction cone. |

| 8 | Rest Room and Contraction Cone | Contraction rate: 7.5 |

| 9 | Total Sitting Area | 47.5m X 17.5m |

In ART, the object itself or its scale model is mounted in the test room where the experiment is made, the wind is given at the desired speed, the model is brought to the desired angle and the aerodynamic forces acting on the model are measured with the help of external balancing or internal balancing systems and current imaging tests can be carried out with various techniques to examine the current.

Until now, TÜBİTAK SAGE, which is the ART Defense Industry companies, has been actively used by universities and civil sector companies, especially ASELSAN, ROKETSAN and TUSAŞ.

In addition, in 2000, ART became a member of the Subsonic Aerodynamic Testing Association (SATA), a worldwide organization established to discuss issues such as the design, operation, maintenance, and physical measurement and instrumentation of the low-speed wind tunnels and to exchange ideas. In ART, a large number of tests were carried out in different categories such as aviation, automotive and civil applications. (Source: defenceturk)

Be the first to comment